New line of

gearboxes with GHA treatment

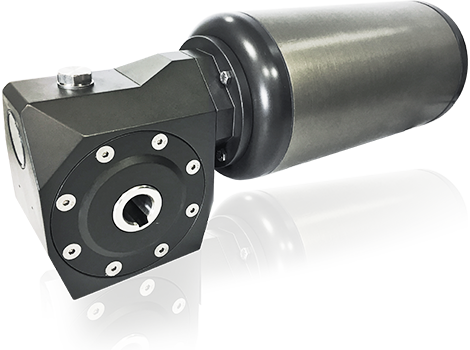

Worm and bevel helical gearboxes with aluminum alloy case, equipped with stainless steel nuts, bolts and hollow output shaft. An exceptional feature of these gearboxes is the innovative patented "GHA" treatment applied to the external and internal surfaces of the gearbox housing, to which it confers extraordinary chemical-physical properties.

What does "GHA" mean?

The "G.H.A." (Golden Hard Anodizing) treatment is the latest and most innovative technology applicable to aluminum-based alloys surfaces. This is an anodic oxidation process enriched with silver ions which gives the treated surface exceptional antibacterial, anti-corrosion, anti-wear and thermal conductivity properties.

The anodic oxidation generates a protective layer of ceramic type, very hard, refractory to heat and unremovable.

Moreover, by means of a patented process, the typical porosities of the anodic oxide crystals are galvanically sealed with silver ions.

The high hardness of the anodic oxide and the uniform distribution of the silver ions guarantee chemical-physical properties of extreme interest for applications in the food, pharmaceutical and marine fields. The GHA gearbox line is an exclusive Tramec patent.

GHA gearboxes features

Antibacterial

ideal for use in aseptic environments

Resistance to corrosion

suitable for use in the marine environment

High thermal conductivity

greater heat dissipation capacity

High surface hardness

high abrasive wear resistance

Product Lines

GHA Classic

GKC worm gearboxes and GTF bevel helical gearboxes

Excellent bactericidal properties

Standard corrosion resistance (250 h in NSS test)

Standard KC and TF housings, subjected to GHA treatment

AISI 316 hollow output shaft and stainless steel nuts and bolts

FDA certified lubricant and oil seals for food industry use

Compliant with HACCP Australia / NZ

GHA Premium

GHA worm gearboxes

Excellent bactericidal properties

Excellent corrosion resistance (over 2016 h in NSS test)

Special housing with smooth external profile, subjected to enhanced GHA treatment, reduces to minimum dirt deposit and allows a better cleaning

High surface hardness of the body with GHA treatment (HV 500-600)

High resistance to abrasive wear

High thermal dissipation

AISI 316 hollow output shaft and stainless steel nuts and bolts

FDA certified lubricant and oil seals for food industry use

Compliant with HACCP Australia / NZ

GHA Modular

GXC worm gearboxes

Excellent bactericidal properties

Standard corrosion resistance (250 h in NSS test)

Standard XC housings, subjected to GHA treatment

AISI 316 hollow output shaft and stainless steel nuts and bolts

Lubricant and oil seals certified by FDA for food industry use

Suitable for use in dry food environments

Feel free to ask for product catalogue!

Leave your e-mail and we will send you the pdf.

GHA electric motors

Thanks to the partnership with company Carpanelli S.p.A., on request the GHA series gearboxes can also be supplied in combination with special, dedicated electric motors, also subjected to GHA treatment and available in two configurations: Classic and Premium.

GHA Classic motors

- Excellent antibacterial properties

- Standard corrosion resistance (250 hours in salt spray NSS)

- IE1 energy class and IP55 protection

- V. 230/400/50 - B5 or B14

- Standard housings in die-cast aluminum alloy with GHA treatment

- Finned external profile

- Good thermal dissipation

- Stainless steel nuts and bolts

- Nylon fan cover

MHA Premium motors

- Excellent antibacterial properties

- Excellent corrosion resistance (over 2016 h in salt spray NSS tests)

- IE4 energy class and IP69K protection

- V. 230/400/50 - S1 - B14

- AISI 420 stainless steel output shaft

- Special aluminum alloy housings subjected to enhanced GHA treatment

- Smooth outer profile minimizes the deposit of dirt and allows better cleaning

- More hygienic thanks to the absence of a fan

- High hardness of the GHA-treated surface (HV 500-600)

- High resistance to abrasive wear

- Excellent thermal dissipation

- High efficiency

- Ability to withstand high voltages, thanks to the non-magnetic characteristics.

- Stainless steel nuts and bolts

Advantages

GHA gearboxes VS stainless steel gearboxes / with other treatments

Thanks to the special properties conferred by the patented treatment to which they are subjected, gearboxes and motors of the GHA series are an excellent alternative to those exclusively made in stainless steel or treated with other processes (i.e. nickel plating or special paintings).

- External surface actively antibacterial vs. inert surfaces, which do not prevent bacterial proliferation

- 1/3 lighter than stainless steel

- Over 13 times higher thermal conductivity (204 W / m ° C) compared to stainless steel (15 W / m ° C)

- Cheaper than the corresponding stainless steel version

- Nickel free

- Non-magnetic motors, capable of withstanding high voltages

- Safe and aseptic

Respect for the environment

They are Eco-Friendly: made with non-polluting and completely recyclable components;

They can be cleaned with ECO-sustainable and non-polluting products with a potentially neutral pH; cleaning with highly polluting products such as sodium hydroxide (caustic soda) is not recommended;

For the production of a GHA reducer much less energy is required than for the corresponding stainless steel product;

Fields of application

GHA gearboxes are ideal for food, chemical-pharmaceutical and marine applications.

Compliance and certifications

TRAMEC’s GHA gearboxes have been tested by accredited laboratories to prove their special characteristics, in accordance with the following standards:

- ISO 22196: 2011 - Antibacterial test - Laboratory results show that, following the criteria imposed by the standard, the GHA Premium sample has 1000 times less bacterial proliferation than untreated aluminum

- ISO 9227: 2017 - Salt spray corrosion test - NSS Test - After 2016 hours of salt spray exposure, the GHA Premium samples show no signs of corrosion.

- RES Annex I chapter 2.1. Applicable to Directive 2006/42 / EC - Food machinery and machines for cosmetic or pharmaceutical products

- SO / IEC 17020: 2012 - Inspection Certificate

- FDA - Food oil and oil seals

Who we are

Founded in 1986, Tramec s.r.l. is specialized in the production of bevel helical, parallel, shaft mounted, right angle, planetary and worm gearboxes.